In the realm of sustainable fashion, the journey from concept to creation is a complex puzzle. At every step, ethical choices matter, and we have taken the time to piece together a supply chain that aligns with our commitment to social and environmental responsibility.

Warming Up for the Season, Sustainably.

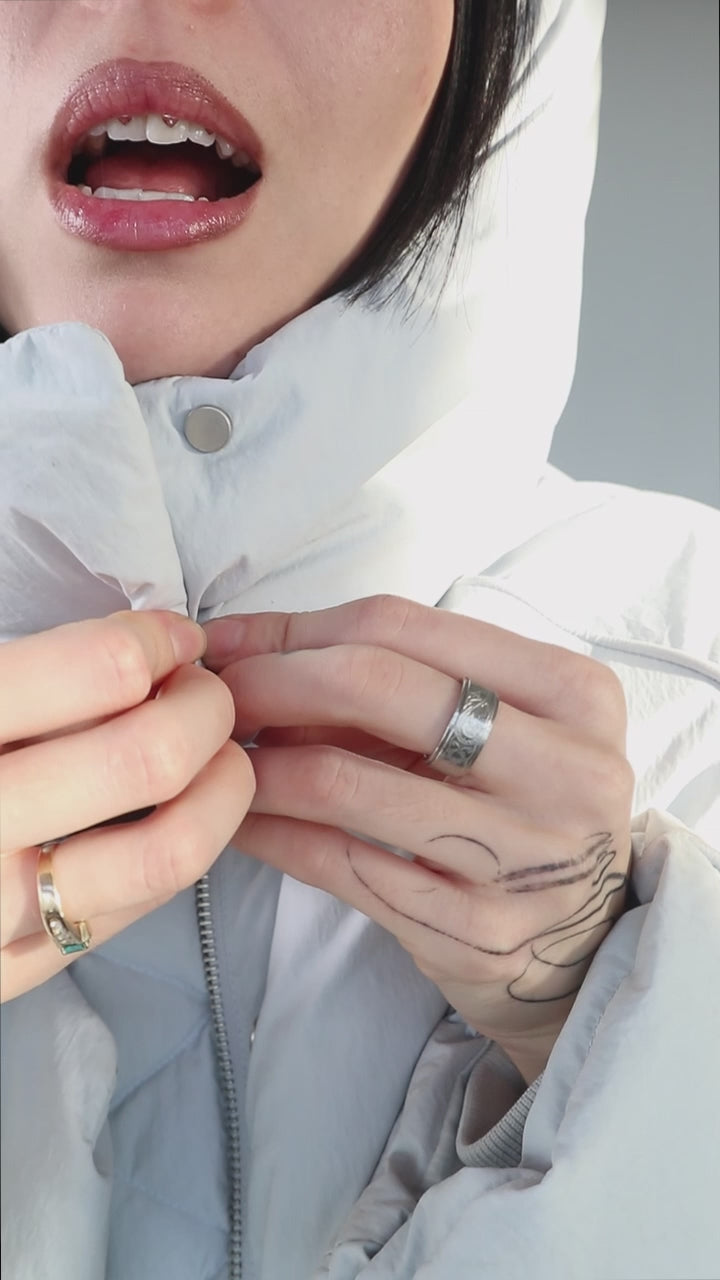

We design for those who appreciate quality and care about the wellbeing of the planet, but still want to enjoy playing around with fashion. After all, the goal is to invest in a good quality puffer jacket that can last us for the many winters to come. With elements of classic styles, through elevated fit and pattern work, our Re:Down Puffer (in cropped and regular length) was born.

Produced at our WRAP (World Responsible Accredited Production®) certified vendor in Vietnam, our puffers are built on GRS certified down, which is 100% recycled, renewed and regenerated from donated items. Re:Down chooses the highest quality of feathers to reuse, and any broken feathers and down that aren’t used are turned into organic fertilizer. Did you know that Re:Down recycles 97% of all the goods collected?

Wait, there's more.

The exterior of our puffer jackets is made of 100% recycled nylon from recycled fabrics, and the baffle/down bag, lining, fleece, and rib cuff are all made of 100% recycled polyester from post consumer fabrics and recycled plastic bottles. Our material suppliers are certified with Bluesign®, Global Recycled Standard, OEKO-TEX®, and Higgs.

Is recycled synthetics really the perfect answer?

No, but it is a step in the right direction for technical outerwear. Outerwear has a lot of components, and it requires durability and longevity - making it complex and challenging to ensure the best ethical and sustainable options are used. We strive for transparency and traceability. The fibers of synthetics are long, making it more durable compared to a natural fiber. We also have sourced 80% of our recycled synthetic from post-consumer materials, rather than plastic.

We ensure every trim in our garments are certified to help create a standard we can trust, and there are also no third-party involvements when it comes to sourcing… because we source every item directly on our own. Currently, we use a total of 6 suppliers for all the materials on our jackets - for a jacket that contains up to 30 different components, this is not bad at all!

One of the largest issues in the garment industry comes from overproduction and overstock, which is why we emphasize on designing with a purpose and function. We create small batches of each style to ensure minimal waste. No room for mass production here. This has allowed us to finely tune our manufacturing processes and ensure your jackets will last season, after season.

With every outerwear we produce, we invite you to join us on this journey towards a more sustainable and conscientious future. Learn more about our sustainable initiatives here.